Bakeries face unique operational challenges that generic fit to all ERP solutions often fail to address. From managing perishable inventory to coordinating production schedules, bakery businesses need specialized systems designed specifically for their workflows. BETs Bakery ERP brings tailored solutions to the industry, helping top bakery brands streamline operations, reduce waste, and boost profitability.

How Bakery Operations Are Different from Other Domains

The bakery industry presents unique operational challenges that set it apart from other manufacturing and retail sectors:

1. Short Shelf Life Management

Unlike many other products, baked goods have extremely short shelf lives—often measured in hours rather than days or weeks. This creates a critical need for precise inventory management, production scheduling, and distribution systems that can handle rapid turnover cycles.

2. Recipe-Driven Production

Bakery production revolves around recipes rather than standard bills of materials. These recipes often involve complex conversion factors between raw ingredients and finished products, with multi-stage production processes that transform semi-finished goods into final products.

3. Temperature-Sensitive Supply Chain

From refrigerated ingredients to temperature-controlled distribution, bakeries must maintain strict environmental controls throughout their supply chain. This necessitates specialized tracking and monitoring capabilities that general ERPs typically lack.

4. Seasonal Demand Fluctuations

Bakeries experience significant demand fluctuations based on holidays, seasons, and special events. Managing these predictable yet dramatic shifts requires sophisticated forecasting and production planning tools tailored to the bakery business cycle.

5. Multi-Channel Distribution Complexity

Modern bakeries often operate across multiple distribution channels simultaneously—retail stores, franchises, HoReCa (Hotel/Restaurant/Café), e-commerce, and wholesale. Each channel has distinct requirements for ordering, packaging, pricing, and delivery scheduling.

6. Batch Traceability Requirements

Food safety regulations demand complete traceability of all ingredients through the production process. Bakeries need systems that can track batches from raw material receipt to customer delivery with precision that exceeds general manufacturing requirements.

7. Customization and On-Demand Production

Unlike many manufacturing operations, bakeries frequently handle custom orders (specialized cakes, personalized pastries) alongside regular production, requiring flexible systems that can seamlessly integrate custom workflows with standard processes

8. Critical Goods Return Management

Returns management in bakeries is uniquely challenging due to the perishable nature of products. When items are returned, rapid decision-making is required to determine whether products can be repurposed, donated, or must be discarded, all while maintaining proper documentation for food safety compliance.

9. Multiple Factors Impacting Production Costs

Bakery production costs fluctuate based on numerous variables including seasonal ingredient price variations, energy consumption for ovens, humidity levels affecting baking times, and labor intensity for decorative items. These complex cost factors necessitate sophisticated cost tracking systems beyond standard manufacturing costing models.

10. Large Product Categories and Subcategories

Bakeries typically manage hundreds or thousands of SKUs across numerous categories (breads, pastries, cakes, cookies) and subcategories (artisan breads, gluten-free options, seasonal specialties), each with unique production requirements, pricing strategies, and shelf-life considerations.

11. A large Number of Recipes

A typical bakery maintains an extensive recipe library, often with hundreds or thousands of formulations that must be precisely followed. These recipes frequently share ingredients but in different proportions, creating complex inventory and production planning challenges.

12. Timely Deliveries and Distribution

The perishable nature of baked goods demands exceptionally precise delivery scheduling and route optimization. Bakeries often operate with delivery windows measured in minutes rather than hours, with products that deteriorate in quality by the hour, creating distribution challenges rarely seen in other industries.

What Are General Expectations of Bakery Leaders from Bakery ERP Solutions

Bakery business leaders have specific expectations from their Bakery ERP systems that reflect the unique challenges of their industry:

1. Business Insights on Fingertips

Bakery executives require instant access to critical business performance metrics and ratios through mobile-friendly dashboards, including Product Contribution Margin (PCM), Hourly Output Efficiency (HOE), Waste-to-Production Ratio (WPR), Sales-per-Labor-Hour (SPLH), Distribution Cost Percentage (DCP), Return Customer Frequency (RCF), Category Mix Performance (CMP), and Fresh-to-Stale Conversion Rate (FSCR). These bakery-specific KPIs enable data-driven decision making while on the production floor or visiting multiple locations.

2. Real-Time Production Tracking

Bakery leaders expect visibility into production status in real-time, with the ability to make rapid adjustments as demand shifts throughout the day. This includes tracking yields, wastage, and production efficiency metrics specific to baking operations.

3. Integrated Recipe Management

Integrated Recipe Management A robust recipe management system is non-negotiable, with capabilities for handling multi-step recipes, ingredient substitutions, batch scaling, costing calculations, and RM-SFG consumption tracking—all integrated with inventory and production. Customized cake production tracking is essential for managing the unique workflow of personalized cake orders, from initial design consultation through production scheduling, decorator assignment, quality verification, and final delivery confirmation, ensuring that each custom creation meets both aesthetic requirements and production timelines.

4. Dynamic Scheduling Capabilities

Bakery operators need scheduling tools that account for equipment capacity, labor availability, temperature requirements, and production sequence constraints unique to baking processes.

4. Franchise and Retail Network Management

For bakeries with multiple locations or franchise operations, centralized control with localized flexibility is essential—allowing headquarters to maintain standards while individual locations manage day-to-day operations.

5. Seamless Distribution and Logistics

Given the time-critical nature of fresh baked goods, bakery leaders expect sophisticated logistics management with route optimization, delivery scheduling, and real-time tracking capabilities.

6. Comprehensive Wastage Control

With perishable products, waste management is crucial to profitability. Bakery leaders need systems that can track, analyze, and help reduce waste throughout the production and distribution process.

7. Regulatory Compliance and Food Safety

Automated tracking of allergens, nutritional information, ingredient sourcing, and production conditions is essential for maintaining compliance with increasingly stringent food safety regulations.

8. Cross-Channel Inventory Visibility

Bakery operators need unified visibility across in-store inventory, warehouse stock, in-transit goods, and production plans to prevent stockouts or overproduction.

Why Generic ERP Products Can't Wait for Bakery Businesses

Generic ERP solutions often fall short for bakery businesses for several critical reasons:

1. They Don't Have Extensions to Manage Extra Plant Activities

Generic ERPs lack the specialized extensions needed for managing bakery-specific plant activities such as ingredient preparation areas, proofing rooms, decorating stations, packaging zones, and quality control checkpoints. These additional production zones, each with unique requirements for temperature, humidity, and workflow management, require purpose-built modules that understand the interdependencies between these areas and their impact on final product quality.

2. Inadequate Recipe Management

Most generic ERPs treat all manufacturing as bill-of-materials based, lacking the nuanced recipe management capabilities essential for bakeries—particularly the ability to handle yield variations, ingredient substitutions, and multi-stage production processes.

3. Limited Shelf Life Management

Standard FG inventory systems aren’t designed to track products with shelf lives measured in hours, creating significant gaps in freshness management and leading to increased waste or quality issues.

4. Insufficient Production Flexibility

The rigid production scheduling in generic ERPs can’t accommodate the dynamic production environment of bakeries, where plans may change multiple times throughout a single day based on sales patterns or ingredient availability.

5. Missing Industry-Specific Metrics

Generic ERPs rarely track the specific KPIs that matter to bakeries, such as waste percentages by product type, yield variations by batch, or seasonal demand patterns for specialty items.

6. Poor Integration with Bakery Equipment

Modern bakery equipment often generates valuable production data that generic ERPs aren’t equipped to capture or analyze, creating information silos and missed optimization opportunities.

7. Lack of Bakery-Specific Distribution Tools

The unique challenges of distributing fresh, fragile products on tight timelines require specialized logistics capabilities rarely found in general-purpose ERP systems.

8. Customization Costs and Complexity

Adapting generic ERPs to meet bakery-specific requirements often requires extensive, expensive customizations that increase implementation time, costs, and ongoing maintenance complexity.

9. Missing Franchise Management Capabilities

Bakeries with franchise models need specialized tools for managing relationships, standardizing operations across locations, and tracking performance metrics relevant to food service businesses.

BETs Strong Use Cases in This Domain

BETs Bakery ERP has established itself as the industry leader through successful implementations across numerous bakery operations, demonstrating exceptional capabilities in the following areas:

1. Integrated Production and Distribution Management

BETs bakery ERP seamlessly connects production planning with distribution logistics, allowing bakeries to optimize both processes simultaneously. This integration ensures freshly baked products reach customers at peak quality while minimizing waste and transportation costs.

2. Multi-Facility Coordination

For bakeries operating multiple production facilities or centralized production with distributed retail, BETs Bakery ERP provides unified control while accommodating location-specific requirements, ensuring consistency across the enterprise.

3. Franchise Network Optimization

BETs Bakery ERP has proven particularly effective for franchise bakery operations, providing headquarters with visibility and control while giving franchisees the tools they need for local success—including specialized apps for daily operations, communication, and inventory management.

4. Recipe and Quality Control Integration

By connecting recipe management directly with quality control processes, BETs bakery ERP ensures consistent product quality across all production batches and locations, maintaining brand standards even as operations scale.

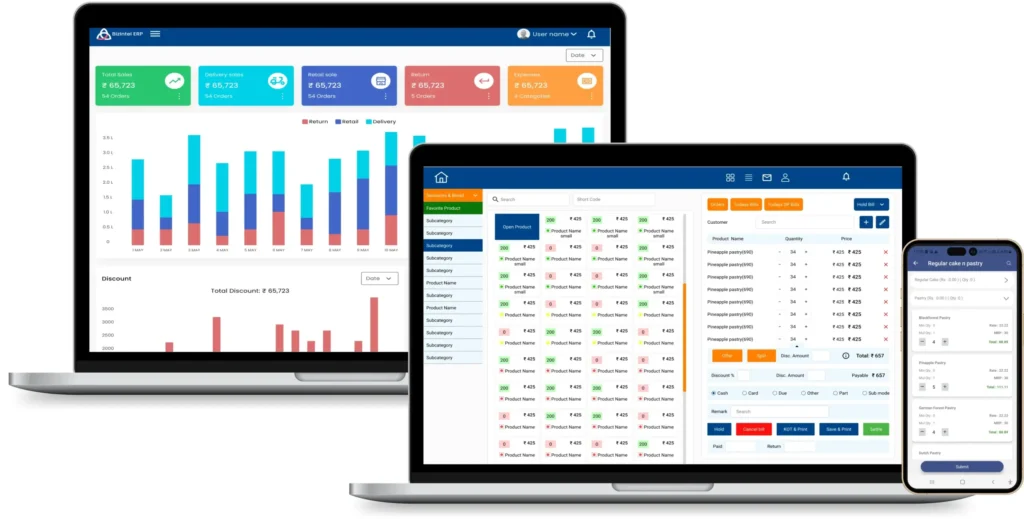

5. Comprehensive Retail Operations Support

For bakeries with direct retail operations, BETs bakery ERP offers integrated POS, customer management, and in-store inventory controls specifically designed for bakery retail environments.

6. Supply Chain Optimization

BETs bakery ERP provides specialized tools for managing bakery-specific supply challenges, including seasonal ingredient availability, temperature-controlled storage requirements, and vendor quality management critical to consistent baking outcomes.

7. Financial Performance Visibility

With bakery-specific financial analytics, BETs bakery ERP gives owners and managers clear visibility into product-level profitability, factoring in all the unique cost drivers of bakery operations that generic systems often miss.

Working for Top Brands

BETs Bakery ERP has established itself as the solution of choice for industry leaders, powering operations for some of the most successful bakery brands nationwide. These partnerships demonstrate not just the system’s technical capabilities but its ability to support business growth and operational excellence at scale.

Leading bakery chains have implemented BETs bakery ERP to standardize operations across hundreds of locations while maintaining the flexibility needed to address local market variations. The system’s robust franchise management capabilities have proven particularly valuable for rapidly expanding brands seeking to maintain quality and consistency during growth phases.

Premium artisanal bakeries rely on BETs bakery ERP to maintain their exacting quality standards while scaling operations beyond single-location limitations. The system’s detailed recipe management and production tracking capabilities ensure consistent execution of complex specialty products across multiple production facilities.

International bakery brands have selected bakery ERP BETs to manage their Indian operations, citing the system’s unique combination of global best practices and localized capabilities that address the specific challenges of the Indian market.

Well Known for with Bakery Challenges

BETs bakery ERP has earned its reputation by solving the most persistent challenges facing bakery businesses:

1. Raw Material Yield Variability

BETs bakery ERP pioneering approach to ingredient management accounts for natural variations in raw materials (particularly flours, fruits, and dairy), allowing bakeries to adjust recipes and production plans dynamically based on actual batch characteristics.

2. Production Scheduling Complexity

The system’s advanced scheduling capabilities handle the complex sequencing requirements of bakery operations, considering factors like oven temperatures, proofing times, and cross-contamination prevention between product types.

3. Multi-Channel Inventory Management

BETs bakery ERP provides unified inventory visibility across all channels—stores, warehouses, in-transit, and production—with specialized tools for managing the ultra-short shelf life items typical in bakery operations.

4. Temperature-Controlled Distribution

The integrated logistics module includes specific features for managing temperature-sensitive deliveries, ensuring product quality is maintained throughout the distribution process.

5. Seasonal Demand Forecasting

BETs bakery ERP advanced analytics provide accurate demand forecasting that accounts for the complex seasonality patterns unique to bakery products, helping businesses prepare for predictable demand spikes.

6. Wastage Reduction

Through integrated analytics and real-time monitoring, BETs bakery ERP helps bakeries identify and address waste sources throughout their operations, significantly improving bottom-line performance.

7. Regulatory Compliance

The system automates compliance with food safety regulations, allergen tracking, and nutritional information requirements, reducing both risk and administrative burden.

BETs Has Everything for Bakery Business

BETs Bakery ERP offers a comprehensive solution that addresses every aspect of modern bakery operations:

1. BETs Procurement & Stores Management System

The procurement module is specifically designed for bakery operations, with features including:

- Comprehensive vendor management with bakery-specific rating criteria

- Ingredient-focused rate contracts and vendor mapping

- Real-time price comparison across vendors for key ingredients

- Specialized tracking for temperature-sensitive and perishable materials

- Batch and expiry date tracking critical for food safety

- Auto-indent creation based on production requirements

- Central store management with temperature zone tracking

- Raw material inspection and quality control workflows

- Automated stock updates and inventory valuations

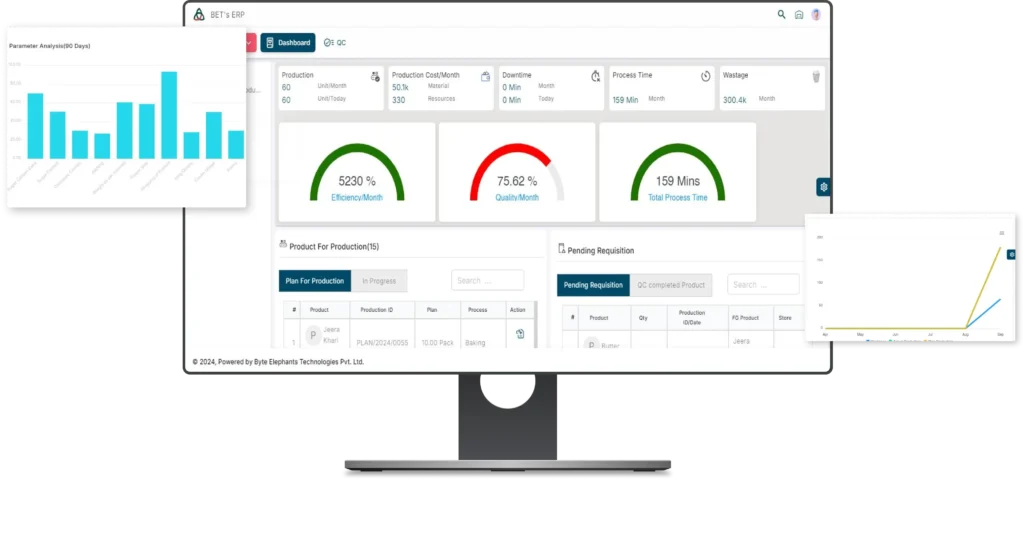

2. Production Management System

BETs Bakery ERP production management capabilities set the standard for bakery operations:

- Advanced production planning tools designed for bakery workflows

- Batch-based production management with complete traceability

- Two-step recipe management linking finished goods to raw materials via semi-finished goods

- Automated material requisition based on production plans

- Production output and variance tracking with reason capture

- Wastage analysis and reduction tools

- Comprehensive rework process management

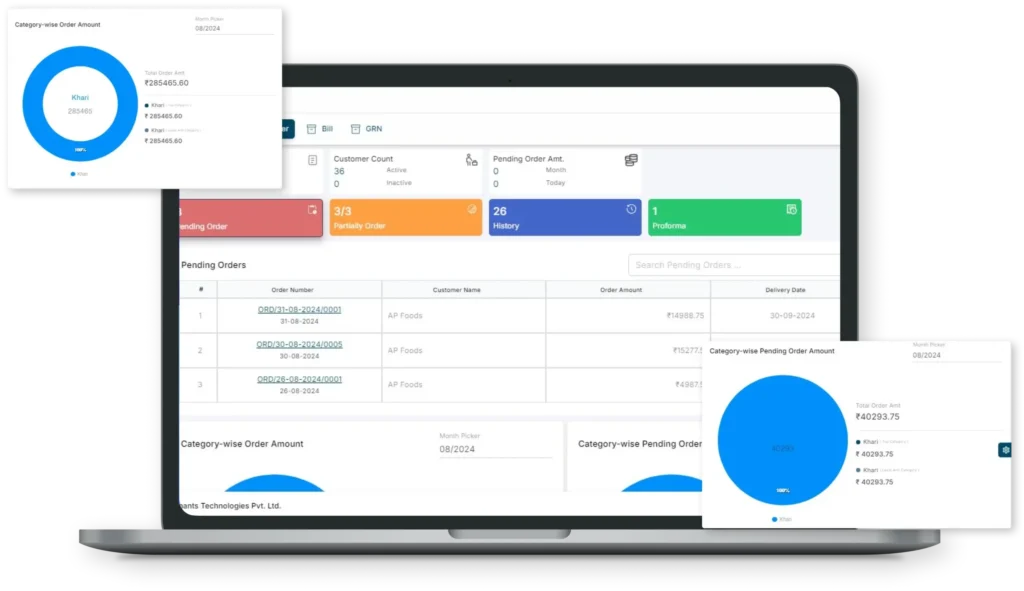

3. Sales Order Processing & Dispatch Management

The sales and dispatch modules streamline order fulfillment with:

- Franchise order processing with customization support

- Consolidated order management for regular, custom, and bulk products

- Production planning directly linked to sales orders

- Route and vehicle optimization for perishable product delivery

- Station-based dispatch management

- Auto-generated loading sheets optimized for product handling requirements

- Real-time vehicle tracking and delivery status updates

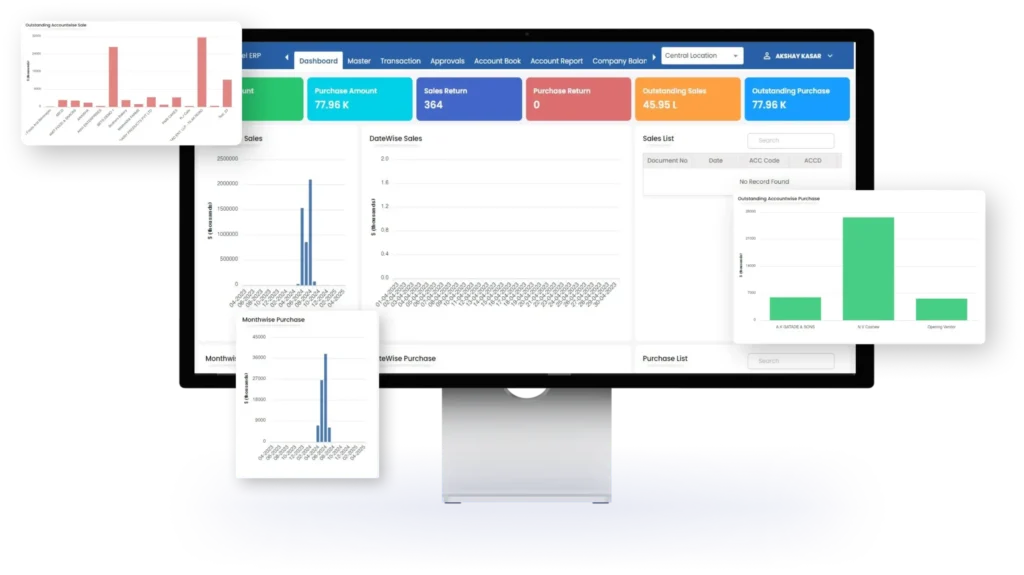

4. Finance & Accounts Management

BETs bakery ERP provides comprehensive financial management tailored to bakery operations:

- GST-compatible invoicing with distributor-specific capabilities

- Multi-currency support for international ingredient sourcing

- Specialized accounting for perishable inventory

- E-way bill and e-invoice integration

- Tally integration options for seamless accounting workflows

- Comprehensive financial reporting with bakery-specific metrics

- Integrated payment processing and gateway connectivity

5. Business Insight App

Decision-makers gain real-time visibility through:

- Mobile access to critical performance metrics

- Detailed sales analysis by category, product, and location

- Top and bottom performing outlet identification

- Trend analysis and predictive analytics

- Offline functionality with automatic syncing

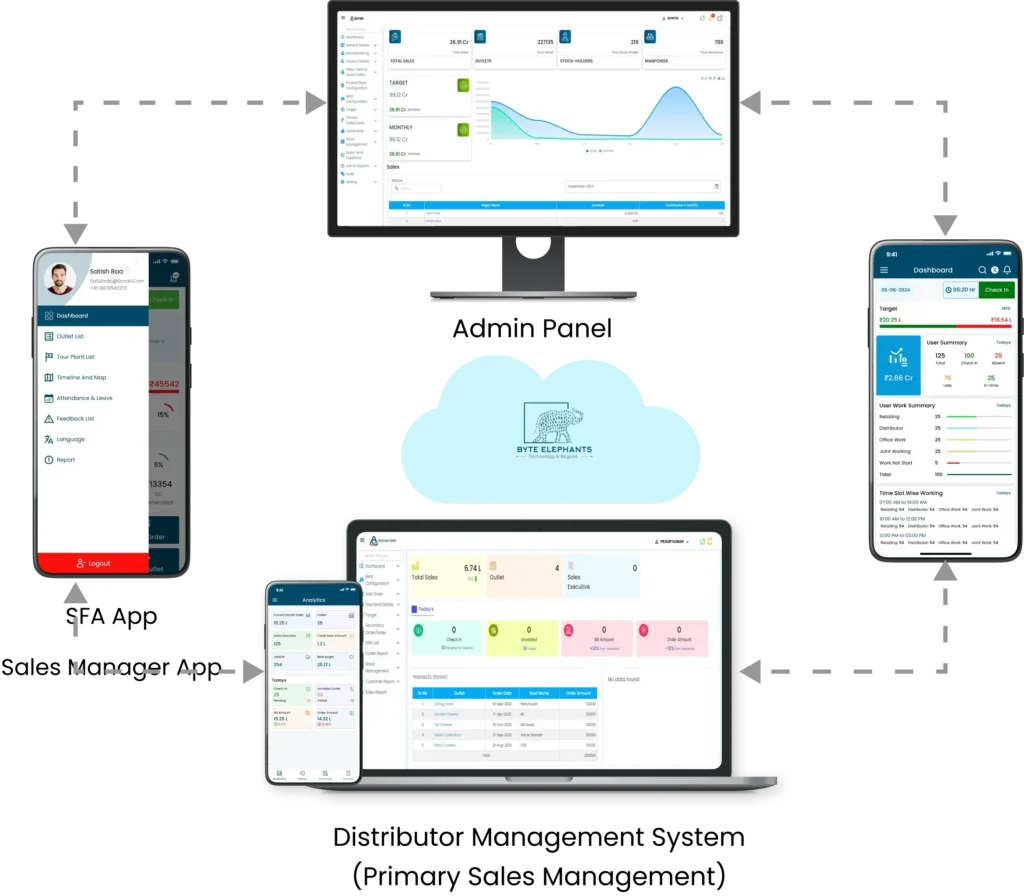

6. SFA-DMS (Sales Force Automation & Distribution Management)

The field sales and distribution module includes:

- Secure mobile authentication with face detection

- GPS-based tracking of field activities

- Beat optimization and allocation

- Target vs. achievement tracking

- Comprehensive visit analysis

- Secondary ordering with stock availability verification

- Remote and offline ordering capabilities

- Merchandising management with photo verification

- New outlet onboarding with duplicate verification

- Integrated HR processes for field teams

- Comprehensive day-end reporting

7. Distribution Management System

For bakery distribution operations, BETs offers:

- Primary ordering with time-controlled booking

- Goods variation and return management

- Secondary order processing with batch tracking

- Institutional sales management with specialized pricing

- Distributor ledger management

- Real-time sales dashboard with performance metrics

8. Franchise Management System (FMS)

Bakery franchises benefit from:

- Time, day, and date-specific order management

- Comprehensive POS system with bakery-specific capabilities

- Integrated inventory management at shop level

- Automated stock monitoring and alerts

- Customer loyalty program management

- Digital album app replacing physical product catalogs

- Franchise-factory communication platform

- Tray management system for tracking returnable assets

- Brand management tools ensuring consistent presentation

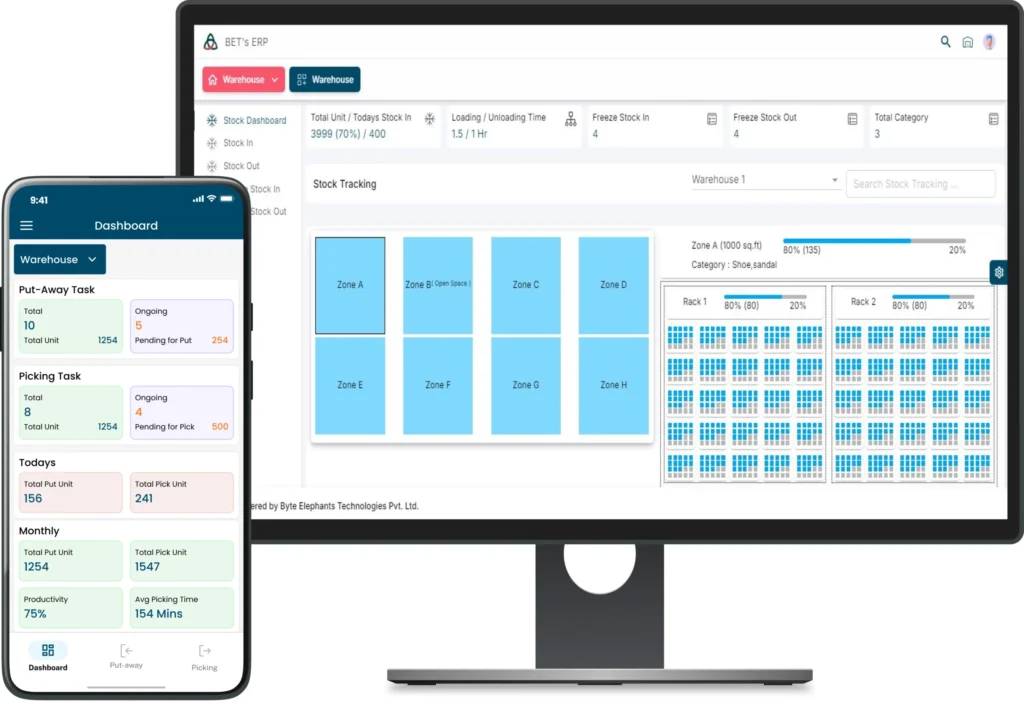

9. Warehouse Management System (WMS)

The warehouse module addresses the unique storage requirements of bakery operations:

- Space planning optimized for temperature-controlled environments

- Zone management for different storage conditions

- Barcode-based material handling

- Optimized put-away and pick-up processes

- Real-time space monitoring and alerts

- Analytics for space utilization and operational efficiency

- Mobile app support for warehouse operations

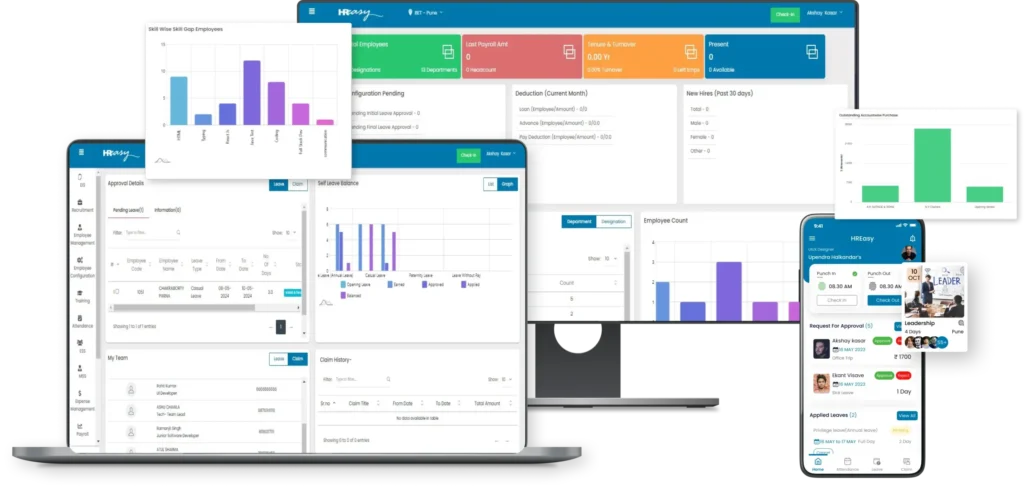

10. HR Management (HREasy)

BETs comprehensive HR capabilities include:

- Recruitment and onboarding management

- Attendance tracking with biometric integration

- Leave management with approval workflows

- Employee document management

- Advance and loan management

- Claim and expense tracking

- Payroll processing with statutory compliance

- Training and performance management

- Rights management for secure access control

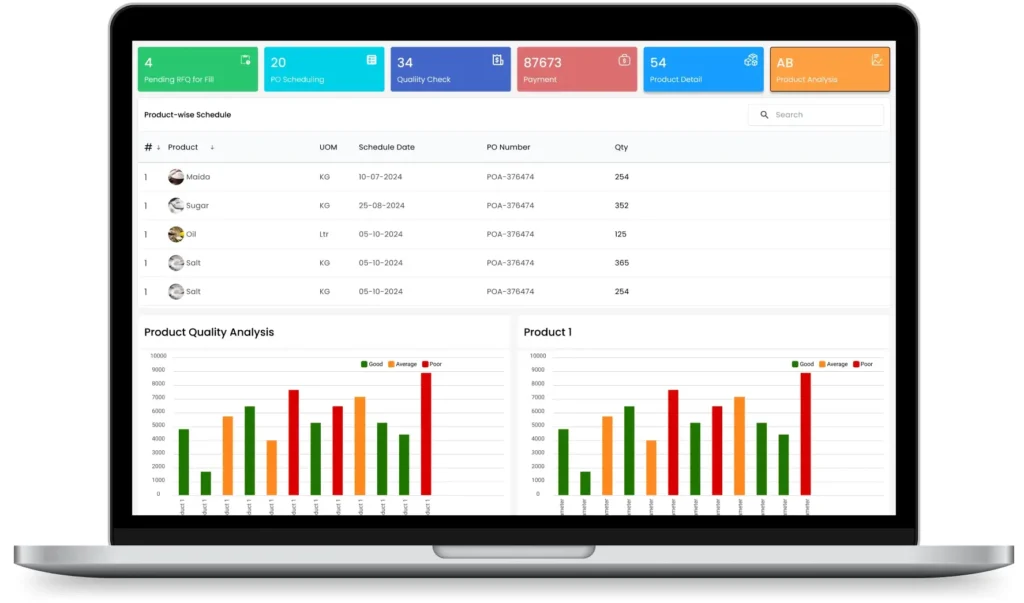

11. Vendor Management System (VMS)

For managing bakery-specific supplier relationships:

- Vendor portal with secure individual logins

- Detailed vendor registration and verification

- RFQ processing and comparative analysis

- Rate contract management

- PO tracking and status updates

- Quality control integration

- Performance metrics and scorecards

- Payment status tracking

- Integration with existing ERP systems

Case study - User Experience

Monginis Case Study: Transforming India's Largest Bakery Network

Monginis, India’s leading bakery brand with 16 manufacturing facilities and over 1,000 franchise outlets across the country, has revolutionized its operations through comprehensive implementation of BETs’ specialized bakery ERP technology ecosystem. The BETs bakery ERP platform seamlessly integrates Monginis’ complex manufacturing processes, vast franchise network, and extensive distribution channels through its purpose-built Bakery ERP, Franchise Management System (FMS), and Point-of-Sale (POS) solutions. This integrated approach has enabled Monginis to standardize product quality across all locations while maintaining the flexibility to address regional taste preferences, optimize their complex supply chain with just-in-time delivery of highly perishable products, and provide real-time visibility into sales patterns across their entire network. The system’s bakery-specific modules for recipe management, production scheduling, and shelf-life tracking have been particularly valuable in maintaining Monginis’ reputation for freshness and quality despite their massive scale of operations. BETs’ specialized franchise management capabilities have simplified Monginis’ relationship with their extensive franchise network, streamlining everything from order placement to quality compliance monitoring, ultimately helping cement Monginis’ position as India’s most trusted and beloved bakery brand.

U2 Cake: From 60 to 200+ Retail Locations

U2 Cake transformed from a modest 40-location bakery chain into a 200+ location powerhouse within 18 months. The system addressed their core challenges like order drop rate, inconsistent recipe execution, high waste rates (15%), frequent stockouts, and labor inefficiencies. BETs’ bakery ERP centralized recipe management ensured quality consistency across all locations, while its predictive analytics reduced wastege. The platform’s inventory management decreased costs, improved labor efficiency and increased average transaction value by 22%. Most critically, BETs bakery ERP conferred confidence to U2 Cake to expand the franchise network & achieve efficient resources management.

Winni: Live Kitchen Implementation

Winni’s unique hybrid bakery-café concept featuring a franchise network with live kitchens. BETs bakery ERP provided customer-facing digital production boards, integrated visible order management, and staff scheduling that balanced technical and presentation skills. The results enabled Winni to replicate their innovative concept across 42 new locations, increasing customer satisfaction by 28%, reducing visible inventory by 64%, decreasing product wait times by 47%, and boosting average check value by 31%. Most significantly, BETs’ integration of customer feedback created a continuous improvement loop that refined both product quality and presentation techniques based on real-time customer reactions.

Conclusion: The BETs Advantage

BETs Bakery ERP represents a paradigm shift in how bakery businesses manage their operations. Unlike generic ERP solutions that require extensive customization to meet industry-specific needs, BETs bakery ERP has been built from the ground up with bakery operations at its core.

This purpose-built approach delivers significant advantages:

1. Faster Implementation

With pre-configured bakery workflows and processes, BETs bakery ERP implementations typically achieve operational status in half the time of generic ERP solutions, providing faster ROI and reduced business disruption.

2. Lower Total Cost of Ownership

By eliminating the need for extensive customizations and providing industry-specific functionality out-of-the-box, BETs bakery ERP reduces both implementation costs and ongoing maintenance expenses.

3. Continuous Industry-Specific Innovation

BETs’ bakery ERP exclusive focus on bakery operations ensures that new features and capabilities are directly relevant to industry needs, providing customers with a constantly evolving solution that keeps pace with market changes.

4. Reduced Operational Risk

With built-in support for bakery-specific compliance requirements and best practices, BETs bakery ERP helps businesses reduce regulatory risks while maintaining operational excellence.

5. Scalable Growth Platform

Whether expanding from a single location to a regional chain or scaling from regional to national operations, BETs bakery ERP provides the technological foundation that supports growth without requiring system replacement.

For bakery businesses serious about operational excellence, customer satisfaction, and profitable growth, BETs Bakery ERP isn’t just a system choice—it’s a strategic advantage that delivers tangible competitive benefits from day one.

The bakery industry’s unique challenges demand specialized solutions. With BETs bakery ERP, bakery businesses gain not just software but a comprehensive operational platform designed specifically for their needs—the competitive edge every bakery brand craves in today’s challenging market.