Food businesses face unique challenges that generic systems simply weren’t designed to address. From managing highly perishable ingredients to navigating complex regulatory requirements, the food industry demands specialized solutions.

Enter BETs Production Management Software—a platform specifically engineered for food businesses. This comprehensive system addresses the distinct needs of food manufacturers, offering targeted solutions that generic alternatives simply can’t match.

The Unique Challenges of Production Management in Food Industries

1. Perishability:

- Unlike manufacturing sectors where raw materials can sit in warehouses for months, food businesses operate under constant pressure of expiration dates

- Every hour counts when dealing with fresh ingredients, creating urgency throughout the supply chain

- Temperature-controlled transportation becomes essential for maintaining ingredient quality

- Seasonal availability of ingredients introduces additional planning complexity

- Fluctuating quality of agricultural inputs requires continuous adaptation of processes

2. Bill of Materials (BOM): Layers of Complexity

- Recipe management in food production isn’t as straightforward as assembling parts in manufacturing

- A single finished product might contain dozens of ingredients, each with their own handling requirements

- Primary ingredients with variable yields create production planning challenges

- Seasonings measured in precise amounts require meticulous quality control

- Processing steps with specific temperature and time parameters demand careful monitoring

- Semi-finished goods (SFGs) become components in multiple finished products, adding complexity

3. Quality Parameters: Multiple Points of Measurement

- Quality control in food production isn’t a single checkpoint—it’s an ongoing process with multiple critical control points

- Raw ingredient quality must be verified upon receipt

- Temperature throughout processing requires continuous monitoring

- Cooking times and methods must be precisely controlled and documented

- Microbial testing is essential for food safety assurance

- Packaging integrity must be verified to maintain product quality

- Shelf-life validation requires ongoing testing and documentation

- Sensory characteristics (taste, texture, appearance) need consistent evaluation

- All parameters must be consistently monitored and documented

4. Seasonality: Nature's Timetable

- Production planning must account for seasonal availability of raw ingredients. This creates challenges for consistent year-round production and inventory management.

- Often necessitates specialized storage solutions for off-season production

5. Regulatory Compliance: Stringent Oversight

- Food safety regulations vary by region and are frequently updated

- Requires meticulous documentation and traceability systems

- Demands regular audits, inspections, and certifications

- Non-compliance can result in product recalls, legal penalties, and reputation damage

6. Contamination Risk: Zero Tolerance

- Production environments require strict hygiene protocols and separation zones

- Cross-contamination between allergens and products demands rigorous controls

- Environmental monitoring becomes a critical production management component

- Equipment design must prioritize cleanability and sanitation

7. Batch Variability: Natural Inconsistencies

- Raw agricultural inputs vary in quality, composition, and characteristics

- Production processes must adapt to accommodate natural variations

- Final product standardization requires sophisticated quality control systems

- Consistent flavor, texture, and appearance profiles are challenging to maintain

8. Supply Chain Complexity: Field to Fork

- Multiple stakeholders from farmers to distributors require coordinated management

- Cold chain integrity must be maintained throughout the supply network

- Transportation logistics are time-sensitive and temperature-critical

- Local and global sourcing creates resilience challenges and sustainability considerations

9. Waste Management: Environmental and Economic Impact

- Production byproducts and rejected materials require specialized handling

- Circular economy initiatives demand innovative approaches to waste streams

- Water usage and wastewater treatment present unique sustainability challenges

- Opportunities for byproduct valorization require dedicated processes and technologies

Why Generic Production Management Software Fall Short

Most production management software were developed for discrete manufacturing industries like electronics or automotive production. These systems operate on assumptions that simply don’t hold true in food manufacturing.

Generic systems typically:

- Lack batch traceability features that accommodate the complexity of food production.

- Don’t integrate with food-specific quality control processes such as HACCP (Hazard Analysis Critical Control Points)

- Struggle with recipe scaling that requires recalculation of production times, not just ingredient quantities

- Can’t effectively manage shelf-life constraints across both ingredients and finished goods

- Provide inadequate support for regulatory compliance documentation specific to food safety standards.

- Lack flexible scheduling capabilities needed to accommodate unexpected disruptions due to raw material quality variations or supply chain irregularities common in food production

- Cannot effectively manage the cleaning and sanitation cycles required between production runs, which impact overall equipment effectiveness calculations

- Don’t account for variable processing conditions based on ambient humidity, temperature, or other environmental factors that significantly impact food production outcomes

These limitations force food manufacturers to create workarounds, maintain separate systems, or simply accept inefficiencies as “part of doing business” in the food industry.

The Real Costs of Using Generic Production Management Software

When food businesses attempt to operate with production management software designed for other industries, the consequences can be severe and wide-ranging:

1. Multi-Level Recipe Management Challenges:

Generic Production Management software struggle with the complex hierarchy of raw materials, semi-finished goods, and multiple packaging levels (primary/secondary/tertiary) common in food production, leading to formula management errors.

2. Variable Batch Size Complications:

Production Management Software not designed for food production cannot easily handle scaling recipes with non-linear relationships between ingredients and cooking parameters, resulting in quality variations.

3. Short Production Timeline Pressures:

The extremely brief production windows for many food products require specialized scheduling capabilities that generic systems lack, causing bottlenecks and delivery delays.

4. Quality Control Integration Gaps:

Food-specific QC processes occurring at multiple production stages require seamless production management system integration that generic platforms don’t provide, creating documentation gaps.

5. Make-to-Order Production Plan Limitations:

Food manufacturers often need to balance made-to-order production with inventory management for perishable ingredients, a complexity generic systems aren’t equipped to handle.

6. FIFO Implementation Failures:

While First-In-First-Out inventory management is critical for food safety and quality, generic systems often lack the granular batch tracking necessary for proper FIFO implementation across complex production scenarios.

7. Increased Food Waste:

Without production management software designed to track perishability and prioritize ingredients nearing expiration, businesses experience higher spoilage rates.

8. Production Inefficiencies:

Food-specific processes like rework (reprocessing unsuccessful batches), managing variable yields, and accommodating seasonal ingredient changes become manual processes, consuming valuable time and introducing errors.

9. Delayed Decision-Making:

When production data is scattered across multiple systems or tracked manually, managers lack the real-time insights needed to make quick adjustments to production schedules.

BETs Production Management Software: Purpose-Built for Food

The BETs Production Management Software was designed from the ground up to address the unique requirements of food manufacturing. Unlike generic alternatives, BETs incorporates features specifically tailored to food production workflows:

Comprehensive Production Planning

- Multi-level production planning for complex recipes requiring semi-finished goods

- Raw material forecasting that accounts for seasonality and perishability

- Resource allocation for equipment with specialized capabilities (mixers, ovens, etc.)

- Advanced scheduling that considers cleaning requirements between product types

- Capacity planning that factors in preparation times, cooking times, and cooling periods

Process Management for Food Manufacturing

- Raw material receiving and inspection with quality parameter tracking

- Semi-finished goods production with interim quality checks

- Packaging material inventory integrated with production needs

- Recipe execution with step-by-step process guidance

- Real-time production monitoring with alerts for deviations

Recipe Management Excellence

- Hierarchical recipe structures for products with multiple components

- Ingredient substitution management for addressing availability issues

- Scaling calculations that adjust both quantities and process parameters

- Version control to maintain records of product evolution

- QC across all ingredients and finished goods with customized QC parameters / reports.

Resource Optimization

- Equipment scheduling that minimizes changeover times

- Utility monitoring for energy-intensive processes like baking or freezing

- Downtime tracking with categorization of causes (cleaning, maintenance, etc.)

- Capacity utilization analysis to identify bottlenecks

Production Metrics that Matter

- Production time tracking broken down by preparation, processing, and packaging

- Cost calculations that factor in yield variations and waste

- Real-time vs. planned production comparisons

- Less/more production tracking to identify variances

- Damage and waste calculation with cause analysis

Finished Goods Management

- Quality control integration with pass/fail tracking

- FIFO (First In, First Out) management through barcode scanning

- Lot tracking for complete traceability

- Shelf-life monitoring with expiration alerts

- Distribution prioritization based on remaining shelf life

Advanced Food-Specific Features

- Rework process management for products that can be safely reprocessed

- IOT/SCADA integration for automated temperature and process monitoring

- Multi-level semi-finished goods tracking from preparation to final assembly

- Simultaneous material requests to multiple storage locations based on BOM requirements

Product Cost Evaluation

- Real-time cost calculation that factors in seasonal price fluctuations for raw materials

- Variance analysis between standard and actual costs with root cause identification

- Yield-adjusted costing that accounts for natural variations in agricultural inputs

- Profitability analysis by product, production line, and customer segment

- What-if scenario modeling for ingredient substitutions and process modifications

Quality Control Integration

- Customizable quality parameters specific to each food category and product type

- In-process quality checkpoints with automated production hold capabilities

- Statistical process control with trend analysis for early deviation detection

- Laboratory test integration for microbiological, chemical, and physical properties

- Automated certificate of analysis generation for regulatory compliance and customer requirements

Material Issue-Issue Return System

- Intelligent material picking based on expiration dates and quality parameters

- Partial material returns with condition assessment for safe reuse determination

- Just-in-time material staging to minimize exposure to ambient conditions

- Automated shortage alerts with suggested substitutions where applicable

- Material usage tracking with real-time yield calculation and deviation analysis

Why BETs Is #1 for Food Industry Production Management Software

BETs has emerged as the leading production management Software solution for food businesses for several compelling reasons:

1. Food-First Design Philosophy

Unlike systems adapted from other industries, BETs Production Management Software was conceived specifically for food production. Every feature, workflow, and data point is relevant to food manufacturing challenges.

2. Scalability Across Food Segments

Whether you’re producing baked goods, prepared meals, beverages, or confectionery products, BETs Production Management Software adapts to the specific requirements of your food category while maintaining consistent traceability and control.

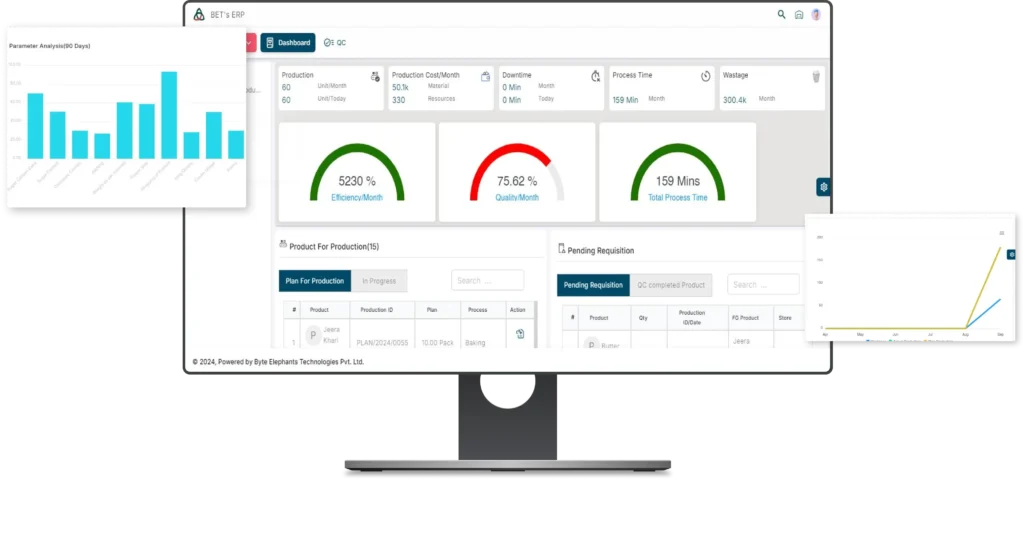

3. Real-Time Visibility Throughout Production

BETs Production Management Software provides dashboards and alerts tailored to different roles—from production line workers to quality managers to executives—ensuring everyone has the information they need when they need it.

4. Integration with the Broader Food Ecosystem

The Production Management Software connects seamlessly with vendor management, distribution logistics, finance, HRMS and regulatory reporting, creating an end-to-end solution for food businesses.

5. Continuous Innovation for Food Manufacturers

As food industry requirements evolve, BETs Production Management Software evolves with them, regularly introducing new capabilities specifically designed for emerging challenges in food production.

6. Multi-Plant Integration Capabilities

BETs Production Management Software seamlessly coordinates production across multiple manufacturing facilities, enabling centralized recipe management, consolidated reporting, and standardized quality control while accommodating plant-specific equipment configurations and production constraints.

7. Platform Approach with Brand-Specific Flexibility

The Production Management Software allows food companies to establish customized SOPs for different brands within their portfolio, maintaining brand-specific quality standards, recipes, and production workflows while leveraging a unified platform for management oversight.

8. Comprehensive Financial Module Integration

BETs Production Management Software provides complete visibility of production costs in financial reporting with features like actual vs. standard cost variance analysis, yield-based profitability tracking, and real-time margin impact calculations that give finance teams unprecedented insight into manufacturing economics.

9. Advanced Business Analytics Suite

The BETs Production Management software delivers industry-specific reports including Shelf-Life Optimization Analysis, Ingredient Utilization Efficiency, Production Line OEE Comparisons, Allergen Management Compliance, Batch Quality Consistency Trends, and Sustainability Metrics that provide actionable intelligence for continuous improvement.

10.. Regulatory Compliance Automation

BETs Production Management Software streamlines compliance with automated HACCP documentation, allergen control verification, nutritional labeling accuracy checks, and audit-ready traceability reporting that dramatically reduces the administrative burden of regulatory requirements.

Case Study: How Kaka Halwai Revolutionized Production Management with BETs

Kaka Halwai Sweets and Namkeen (KHSC), a six-generation legacy brand in Pune operating 3 manufacturing plants faced significant challenges managing their extensive production of over 100+ different sweet and snack varieties.

Challenge

Prior to implementing BETs, Kaka Halwai faced significant challenges in coordinating operations across their three manufacturing plants. With increasing demand and expanding product lines, their legacy systems struggled to maintain consistency, ensure quality standards, and optimize resource allocation across facilities.

Solution: Comprehensive Production Management Software

The cornerstone of Kaka Halwai’s transformation has been BETs’ integrated production management software, which addresses multiple dimensions of their manufacturing operations:

1. Multi-Plant Coordination

BETs ERP enabled Kaka Halwai to centralize production planning and execution across all three manufacturing facilities. The system standardized processes, aligned production schedules, and eliminated redundancies. This centralized approach ensures that all plants adhere to identical quality parameters, production methodologies, and resource utilization standards.

2. Automated Material Requirements Planning

The production management Software features automated Bill of Materials (BOM) functionality that revolutionized Kaka Halwai’s approach to materials management:

- Auto-requisition system: Automatically triggers raw material requests based on production schedules

- Demand forecasting: Utilizes historical data to predict material requirements

- Just-in-time production: Minimizes inventory holding costs while ensuring materials availability

3. FIFO and Batch Tracking

The BETs Production Management Software implemented rigorous FIFO principles and batch tracking capabilities throughout the production cycle:

- Raw materials are meticulously tracked from receipt to utilization

- Semi-finished goods maintain their batch identity through each production stage

- Finished products carry complete manufacturing lineage information

This systematic approach has significantly enhanced quality control, simplified compliance with regulatory requirements, and improved recall management capabilities.

4. Inventory Integration

The production management software maintains seamless integration between Raw Materials (RM), Semi-Finished Goods (SFG), and Finished Goods (FG) inventories across all plants. Real-time visibility enables production managers to make informed decisions about:

- Material allocation across facilities

- Production sequencing optimization

- Work-in-progress management

- Finished goods distribution

Results

The implementation of BETs’ production management software has delivered substantial benefits to Kaka Halwai:

- Enhanced operational efficiency: Production cycles have been streamlined, reducing waste and optimizing resource utilization

- Improved quality control: Batch tracking enables precise quality management and rapid response to any issues

- Reduced production costs: Better resource planning and allocation have decreased overall manufacturing expenses

- Increased agility: The production system allows Kaka Halwai to quickly adjust manufacturing outputs based on market demand

- Better financial visibility: Complete integration with accounting systems provides accurate production cost analysis

By transforming their production management through BETs ERP Suite, Kaka Halwai has established a scalable, efficient manufacturing operation that positions them for continued growth in the competitive Sweets & Namkeen market.

Conclusion: Transform Your Food Production with BETs Production Management Software

In the food industry, razor-thin margins and ever-increasing quality expectations leave no room for inefficiency. Food businesses cannot afford to operate with production management software designed for other industries. The unique challenges of perishability, recipe complexity, and rigorous quality requirements demand specialized solutions.

Forward-thinking food business leaders recognize that production management isn’t just about tracking inventory and scheduling production runs. It’s about orchestrating a complex symphony of ingredients, processes, equipment, and people to create consistent, high-quality food products that delight customers and meet regulatory requirements..

BETs isn’t just a production management software; it’s a competitive advantage that allows food manufacturers to focus on what they do best—creating exceptional food products—while the system handles the intricate details of production management with food-specific precision.

For food businesses ready to eliminate waste, enhance quality consistency, ensure compliance, and maximize profitability, the choice is clear. BETs Production Management System isn’t just a solution—it’s the solution specifically engineered for food manufacturing excellence.