Kaka Halwai Sweets and Namkeen (KHSC) is a well-known name synonymous with the richness and sweetness of Pune. With over six generations of history, the brand has been a trusted name for producing top-quality mithai and namkeen. From humble beginnings to becoming a household name in the region, KHSC continues to serve fresh, delectable products to customers not only in Pune but across the world.

Kaka Halwai operates three manufacturing plants and 25 sales outlets (including franchises) in Pune, handling high foot traffic, especially during festival seasons when demand for traditional sweets and snacks surges.

1.1. KHSC’s Scale of Operation

- Manufacturing Plants: 3 strategically located manufacturing units producing sweets, snacks, and namkeens, all adhering to strict quality controls.

- Sales Outlets: 25 sales outlets, including multiple franchises, with high customer volumes, especially during festivals.

- SKUs: Over 100+ different products (sweets, snacks, and namkeen varieties) are offered to cater to diverse customer preferences.

1.2. Industry-Specific Hurdles at KHSC

KHSC was facing a set of unique operational challenges, for which they turned to technology for resolution.

- Perishable Goods Management: With a variety of products ranging from raw materials to finished goods, the challenge was to efficiently manage inventory while ensuring freshness and minimizing wastage. Managing raw materials, semi-finished goods, and finished products was critical to reduce spoilage and maximize shelf-life.

- Quality Control (QC): Maintaining high standards for taste and freshness across multiple locations was crucial. Any inconsistency in the production process could affect the brand’s legacy and customer loyalty.

- Demand Forecasting: Predicting demand during peak seasons (festivals) while balancing inventory was essential for smooth operations. Inaccurate forecasting led to either stockouts or excess wastage.

- Recipe Management: Maintaining recipe consistency was vital for the brand’s promise of authentic taste. Any deviation could result in a loss of customer trust.

1.3. Before the Transformation: KHSC’s Previous System

KHSC initially relied on an internationally prominent ERP system and a POS system from another vendor. However, these solutions did not fully address the complexities of managing an Sweets & Namkeen-specific operation.

i. ERP :

Though internationally recognized, the ERP system did not offer features specific to the Sweets & Namkeen industry, less adaptive to local procedures, short of agility and lacked necessary customizations for the brand’s needs.

II. POS System:

The POS system did not integrate well with their operations and failed to provide the necessary control over inventory, sales, or customer data.

III. Low Cost to Benefit Ratio:

Despite high investment, the systems did not provide the expected return on investment in terms of operational efficiency or scalability.

IV. Multiple Systems and Vendors:

Managing multiple software platforms and vendors proved to be cumbersome, with scattered data across systems, which led to inefficient workflows & multiple data entry tasks.

V. Limited End-to-End Control:

There was no cohesive system to manage operations from manufacturing to sales, which limited the visibility and control over the entire business process.

VI. Lack of Production Batch Tracking:

The previous system at KHSC did not have the capability to effectively track production batches. This resulted in challenges such as difficulty in monitoring the quality and consistency of products, delays in identifying and resolving production issues, and an inability to trace the origin and movement of raw materials and finished goods throughout the production process.

VII. Lack of Backward & Forward Integrations:

The absence of backward and forward integrations in the previous system meant that KHSC struggled with seamless communication between various stages of the supply chain. “Backward integration” refers to the inability to connect effectively with suppliers and track raw material sourcing and quality. “Forward integration” refers to challenges in managing the distribution and delivery of finished products to customers. Without these integrations, KHSC faced inefficiencies in procurement, order fulfillment, and customer demand forecasting, which ultimately affected overall operational performance, responsiveness, and customer satisfaction.

Implementation of BETs Systems: Kaka Halwai’s Journey to Operational Excellence

After evaluating several options, Kaka Halwai chose BETs ERP Platforms for their specialized, end-to-end software solutions designed specifically for the Sweets & Namkeen industry. Here’s why:

I. Domain Expertise

BETs has deep expertise in the Sweet & Namkeen sector and understands the unique operational needs of brands like Kaka Halwai. Their solutions are tailored to meet the specific challenges of –

- Managing perishable goods

- Multilevel Inventory Tracking

- Critical inventory management of RM / SFG / FG

- Dynamic Order Processing and demand forecasting.

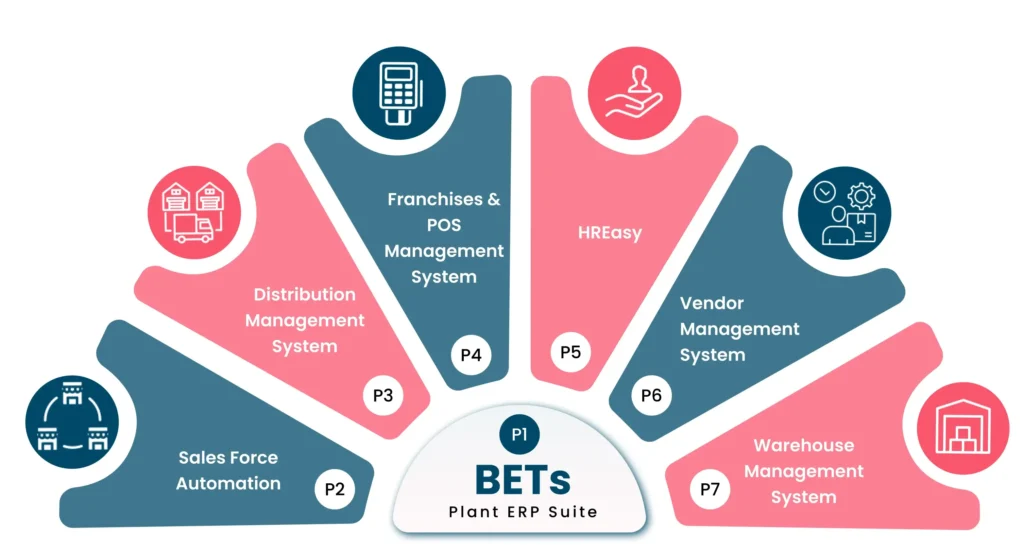

II. BETs End to End ERP Platforms:

BETs provides a comprehensive end-to-end ERP platforms tailored for the Sweet & Namkeen industry, covering all critical areas from manufacturing to sales and distribution. The platform includes the following key components:

- P1-Manufacturing ERP Suite : A robust system designed to streamline production processes, manage resources, and ensure efficiency throughout the manufacturing cycle.

- P2-Sales Force Automation: Automates and optimizes sales processes, helping sales teams track leads, manage customer interactions, and drive growth.

- P3-Distribution Management System: Manages the flow of products from manufacturing to customers, ensuring smooth distribution and timely deliveries.

- P4-Franchise Management System: Helps manage and support franchise operations, ensuring consistent quality and efficient operations across all franchise locations.

- P5-POS System: A point-of-sale system that facilitates sales transactions, inventory tracking, and real-time reporting.

- P6-HREasy: A Human Resource Management solution that simplifies payroll, employee data management, and performance tracking.

- P7-Vendor Management System: Enables efficient management of supplier relationships, procurement processes, and supplier performance monitoring.

- P8-Warehouse Management System: Optimizes inventory control, order fulfillment, and storage management in warehouses.

III. Platform-Based Approach:

BETs’ modular ERP platforms provide the flexibility to configure the system as per the unique requirements of the brand. Brand can start by prioritizing any of the platforms based on their immediate needs, and gradually optimize the entire system to improve operational efficiency and performance.This allowed KHSC to have a configured solution without having to deal with rigid, one-size-fits-all systems.

IV. Seamless Integration:

BETs’ solutions provide seamless integration across various modules & hardwares as well including ERP Platforms, Franchise Management, and Sales, Weighing scale ensuring end-to-end control over operations. This integration enables smooth communication between all touchpoints and improves overall efficiency.

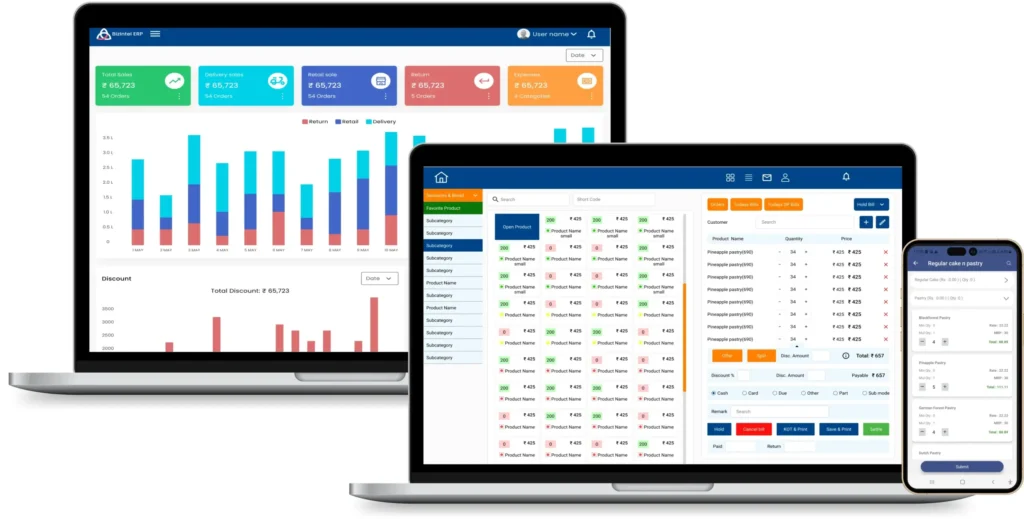

BETs Systems Implementations

3.1. ERP Implementation

BETs implemented a comprehensive ERP Platforms at KHSC’s 3 manufacturing plants. The system integrated operations across the plants and provided better communication and control over key areas:

i. Vendor Management :

BETs’ ERP Platforms helped KHSC streamline vendor relationships, rate contracts, ensure on-time deliveries, quality materials, and better vendor performance monitoring. The vendor performance matrix helped KHSC maintain a steady supply of high-quality raw materials without hampering bottomline.

II. Procurement :

BETs’ ERP Platforms helped KHSC streamline vendor relationships, rate contracts, ensure on-time deliveries, quality materials, and better vendor performance monitoring. The vendor performance matrix helped KHSC maintain a steady supply of high-quality raw materials without hampering bottomline.

III. Stores Management:

The system provided real-time visibility into stock levels across different warehouses and manufacturing plants, enabling effective stock management. This feature helped reduce overstocking and understocking, ensuring smooth production operations.

IV. Production Management:

BETs’ ERP Platforms streamlined production scheduling, ensuring that the manufacturing process runs efficiently without disruptions.

- Real-time tracking of production status and workflows improved transparency and coordination, enabling seamless communication across departments.

- The system supports both Make-to-Order (MTO) and Make-to-Stock (MTS) production strategies, catering to diverse business needs.

- It integrates Recipe Management for consistent product quality and accurate formulation.

- Advanced Production Planning accounts for multilevel mapping of Semi-Finished Goods (SFG) with Finished Goods (FG) to optimize resources and timelines.

- The platform also tracks overheads in production, performs wastage analysis, and monitors breakdowns to reduce downtime.

- Key performance metrics like Turnaround Time (TAT) are measured for operational efficiency.

V. Accounting & Finance:

BETs’ ERP platforms provided a centralized accounting platform for KHSC, automating critical financial processes like billing, invoicing, and payment tracking. This not only reduced manual errors but also improved the accuracy and timeliness of financial reporting.

- The system includes robust Voucher Management for seamless recording of transactions and GST Reports to ensure compliance with tax regulations.

- Comprehensive Ledger Management simplifies tracking and analysis of financial data.

- Features like Auto E-Invoice and E-Way Bill Integrations streamline documentation for regulatory adherence.

- The platform facilitates Bank Reconciliation to match and verify financial records with bank statements, ensuring accuracy in cash flow management.

- It also supports the preparation of key financial statements, including Profit & Loss (P&L) reports, Trial Balances, and Audit Trails, providing a transparent and systematic view of financial operations. With these capabilities, KHSC achieved enhanced financial control and streamlined decision-making.

VI. Sales Order Management:

The integration of sales order management within the ERP platforms empowered KHSC to efficiently track and process orders, ensuring timely dispatch and preventing delays, especially during high-demand periods like festival seasons.

VII. Dispatch & Logistics:

BETs’ ERP platforms automated the dispatch process and integrated it with the logistics module. This ensured that orders were dispatched on time and tracking was easy, leading to better customer satisfaction.

3.2. Franchise Management System Implementation

BETs’ Franchise Management System (FMS) was implemented across KHSC’s sales outlets, including its franchises:

I. Ordering System:

BETs’ ERP Platforms significantly streamlined the ordering process for franchises, enabling them to place orders quickly and efficiently. It supports various types of orders catering to different business including;

- Regular Orders

- Customized Orders

- Corporate Orders

- Bulk Orders,

- Advance Orders

Additionally, automated order processing reduces human errors, improves order accuracy, faster order fulfillment, better tracking,

II. POS with Token System:

The Token-Based POS System is ideal for managing high footfall in sweet shops with multiple menu-specific counters. Customers visit different counters and scan a QR-based token to place their orders, eliminating the need for multiple payments at each counter. At the cash counter, all orders linked to the token are consolidated, enabling quick and hassle-free billing. This system significantly reduces queue congestion, speeds up service, and improves order accuracy, making it highly efficient during peak hours and festive seasons. It also enhances operational control, ensuring a smooth experience for both customers and staff..

III. Inventory Management:

Effective inventory management is critical for franchise operations to ensure consistent product availability, reduced wastage, and streamlined replenishment processes. BETs ERP platforms offers a centralized Franchise Inventory Management System, enabling seamless coordination between manufacturing plants and franchise outlets.

IV. CRM & Customer Loyalty Program:

BETs FMS enhances customer engagement through an integrated CRM & Customer Loyalty Program, helping franchises build long-term relationships and drive repeat business. The system captures customer purchase history, enabling personalized promotions and targeted marketing campaigns. Additionally, data-driven insights enable franchises to tailor offers, enhancing customer retention. This approach fosters brand loyalty while boosting sales and customer satisfaction.

V. Auto Good Returns Management:

The system simplified returns management by tracking goods returned by Franchisees, maintaining proper documentation, and allowing easy credit note generations & refunds. This improved the relationship between KHSC and its franchisees.

VI. Weighing Scale Integration:

BETs’ FMS integrated weighing scales with the POS system to ensure accurate pricing based on product weight, ensuring minimum data entry & minimum serving time to customers.

4. The BETs Effect: Key Outcomes for Kaka Halwai

The implementation of BETs ERP Suite at Kaka Halwai Sweet Center has revolutionized their operations, setting a benchmark for efficiency and scalability in the Sweets & Namkeen domain. Here are the key outcomes that have propelled their business forward:

1. Seamless Integration of Operations Across 3 Manufacturing Plants

BETs facilitated the unification of operations across Kaka Halwai’s three manufacturing plants by centralizing production planning, aligning schedules, and standardizing processes. This approach minimized redundancies, enhanced inter-plant coordination, and ensured consistency in resource allocation and quality control. This integration ensures consistency in production, quality, and resource utilization across all facilities.

2. Total Backward & Forward Integrations:

BETs ERP platforms has enabled comprehensive backward and forward integration, ensuring seamless coordination between procurement, production, sales, and distribution processes.

- Backward Integration: The system optimizes vendor management, procurement, quality control (QC), and stores management, ensuring efficient raw material sourcing. Auto requisition (BOM) in production management automates stock replenishment, reducing manual intervention. Additionally, the ERP platforms ensures accounts reflection of purchased goods and production overheads, enhancing financial transparency.

- Forward Integration: The ERP integrates production management, FG inventory management, order processing, dispatch & logistics, order placement, point-of-sale transactions, and goods return management. This ensures smooth fulfillment operations, while accounts reflection of sales, supply chain overheads, and P&L tracking provides a comprehensive financial overview.

- By achieving end-to-end integration, BETs ERP platforms has streamlined Kaka Halwai’s entire value chain, improving operational efficiency and financial control.

3. FIFO and Batch Tracking of Raw Materials, Semi-Finished Goods, and Finished Goods

The ERP platforms ensures stringent adherence to FIFO (First-In, First-Out) principles and robust batch tracking mechanisms. For example, raw materials are utilized in the order they are received, reducing spoilage and ensuring product freshness. Batch tracking has enabled quick identification of specific production lots, significantly improving recall management and quality assurance. This enhances inventory accuracy, minimizes waste, and ensures traceability throughout the production cycle, from raw materials to finished goods.

4. Integrated RM-SFG-FG Inventory Across All Plants

With a centralized inventory management system, BETs ERP platforms provides real-time visibility into Raw Materials (RM), Semi-Finished Goods (SFG), and Finished Goods (FG) inventories across all three plants. This integration reduces stockouts, prevents overstocking, and optimizes supply chain efficiency.

5. Seamless Communication Between Franchisees and Manufacturing Plants

BETs ERP Platforms has bridged the communication gap between franchisees and manufacturing units by leveraging centralized dashboards, automated notifications, and real-time reporting tools. These features ensure smooth coordination, timely order processing, and transparent communication across all stakeholders. Real-time data sharing and automated order processing streamline demand fulfillment, enabling faster response times and enhanced collaboration.

6. Enhanced Franchisee Efficiency to Manage High Footfall

Franchisees are now equipped with tools to handle peak footfall efficiently. The system’s optimization capabilities ensure faster billing, improved inventory replenishment, and enhanced customer experience during high-demand periods.

7. Total Control Over End-to-End Operations

BETs ERP Platforms provides complete oversight from manufacturing to sales and distribution. The end-to-end visibility empowers management with actionable insights to monitor KPIs, optimize processes, and enforce operational controls seamlessly.

8. Domain-Specific Configurations for Better Adaptability

The ERP’s domain-specific configurations are tailored to the unique requirements of the Sweets & Namkeen industry. For example, it includes modules specifically designed to manage perishable inventory, allowing automated shelf-life tracking and ensuring that products nearing expiration are prioritized for sale or repurposing. This customization ensures high adaptability and delivers outcomes aligned with Kaka Halwai’s business objectives.

9. Structured Data for Data-Driven Decision Making

The homogeneous system generates structured, comprehensive data that supports analytics and reporting. For instance, this data enabled Kaka Halwai to identify seasonal demand trends, allowing them to optimize production schedules and inventory levels. This insight not only reduced wastage but also ensured timely availability of high-demand products, enhancing customer satisfaction. This data-driven approach empowers leadership to make informed decisions, improving strategic planning and operational efficiency.

Byte Elephants Technologies (BETs) has not only enhanced the operational backbone of Kaka Halwai but has also positioned them for sustained growth and competitive advantage in the market. Their journey showcases the transformative power of a well-implemented ERP system.

Conclusion

Byte Elephants Technologies (BETs’) ERP platforms implementation at KHSC exemplifies the unique approach and expertise that set them apart from other solution providers. By seamlessly phasing out old systems and phasing in integrated platforms, BETs ensured minimal disruption and maximum efficiency.

Through domain specific ERP solutions and unmatched industry knowledge, BETs continues to empower brands like KHSC to preserve their legacy while embracing innovation for future growth.