Enterprises across industries are constantly seeking ways to streamline operations, reduce costs, and improve efficiency. Enterprise Resource Planning (ERP) systems in Supply Chain Management (SCM) have emerged as the backbone of modern business operations, promising to integrate various business processes and functions into a unified system. However, reality often falls short of expectations.

Many organizations find themselves using ERP solutions that only address partial aspects of their operations, creating silos of information and preventing true end-to-end visibility in SCM. This partial integration leads to inefficiencies, data inconsistencies, and missed opportunities for strategic decision-making.

1. ERP Products in Market with Limited Operations Coverage

The current ERP landscape is fragmented, with many solutions focusing on specific operational areas while neglecting others. This limitation forces organizations to adopt a patchwork approach to manage their end-to-end operations in SCM, resulting in significant challenges:

The Patchwork Approach to Operations Management

Organizations typically resort to managing their operations through:

- Multiple disparate software products: Companies often use different software for finance, inventory, production, sales, and other functions, with minimal integration between them.

- Google Sheets and spreadsheets: To bridge gaps between systems, employees frequently resort to creating and maintaining elaborate spreadsheets for tracking, reporting, and analysis.

- Manual processes: Critical business information is manually transferred between systems, leading to delays, errors, and inefficiencies.

- Excessive data entry tasks: Staff members spend countless hours inputting the same data into multiple systems, reducing productivity and increasing the risk of errors.

2. What is Upstream Supply Chain?

The upstream supply chain in SCM encompasses all activities, processes, and relationships that occur before the manufacturing or production stage. This critical segment focuses on the flow of raw materials and components from suppliers to the manufacturing facility.

Key Components of the Upstream Supply Chain

- Vendor Management: Establishing and maintaining relationships with suppliers, including vendor selection, evaluation, and performance monitoring.

- Procurement: The process of sourcing and purchasing raw materials, components, and services needed for production.

- Inbound Logistics: Coordinating the transportation, receipt, and storage of incoming materials.

- Stores Management: Organizing and controlling the inventory of raw materials and components before they enter production.

- Production Planning: Scheduling and coordinating manufacturing activities based on material availability and demand forecasts.

The upstream supply chain in SCM sets the foundation for successful manufacturing operations. Efficient upstream processes ensure that the right materials are available at the right time and at the right cost, which directly impacts production capabilities and overall operational efficiency.

3. What is Downstream Supply Chain?

The downstream supply chain in SCM encompasses all activities that occur after the manufacturing or production process, focusing on getting finished products to the end customers.

Key Components of the Downstream Supply Chain

Sales Force Automation (SFA): Empowering sales teams with tools and information to effectively sell products, manage customer relationships, and capture market opportunities.

Distribution Management System (DMS) : Coordinating the movement of finished goods from production facilities to primary distributors, wholesalers, etc.

- Franchise Order Processing System (FMS): Maintaining consistent operations, quality, and brand experience across franchised locations while managing franchise relationships.

- Point of Sale (POS) Systems:

Capturing sales transactions at retail locations, including inventory updates, payment processing, and customer data collection.

- Warehouse Management:

Efficiently storing, picking, packing, and shipping finished goods to meet customer demand while minimizing costs.

The downstream supply chain in SCM directly influences customer satisfaction, brand reputation, and revenue generation. Efficient downstream processes ensure that products reach customers in a timely manner and at optimal cost.

4. Why Both Supply Chains Should Work in Sync

The integration of upstream and downstream supply chains in SCM creates a holistic view of operations that drives efficiency, responsiveness, and competitive advantage. When both sides of the supply chain work in harmony, organizations experience numerous benefits:

Benefits of Synchronized Supply Chains

- End-to-End Visibility: Complete visibility across the entire supply chain enables more effective planning and execution.

- Demand-Driven Production: Production plans can be directly informed by downstream sales data and demand forecasts.

- Inventory Optimization: Coordinated inventory management across the entire supply chain minimizes holding costs while ensuring availability.

- Reduced Lead Times: Streamlined processes and improved communication reduce delays and accelerate order fulfillment.

- Improved Cash Flow: Synchronized operations optimize working capital by aligning procurement with actual demand.

- Enhanced Customer Service: Better coordination leads to improved order accuracy, on-time delivery, and overall customer satisfaction.

- Agility and Responsiveness: Organizations can quickly adapt to changing market conditions, customer preferences, and supply disruptions.

When upstream and downstream supply chains operate as a unified system rather than separate entities, organizations can achieve a level of operational excellence that drives sustainable growth and profitability.

5. Challenges if Both Systems Won't Be in Sync

When upstream and downstream supply chain systems operate in isolation, organizations face significant challenges that impact operational efficiency, financial performance, and customer satisfaction:

Operational Challenges

- The Bullwhip Effect: Small fluctuations in retail demand can cause increasingly larger fluctuations in orders at wholesale, distribution, manufacturing, and supplier levels, leading to:

- Excessive inventory

- Poor customer service

- Lost revenues

- Inefficient production

- Transport and shipping problems

2. Inventory Imbalances: Without synchronization, organizations often experience:

- Overstocking in some locations

- Stockouts in others

- Excess obsolete inventory

- Emergency shipments and production runs

3. Production Inefficiencies:

- Manufacturing based on outdated or incomplete demand information

- Frequent production schedule changes

- Inefficient resource utilization

- Higher production costs

Information Challenges

- Data Inconsistencies: Different systems maintain different versions of the same information, leading to confusion and errors.

- Decision Latency: Time-consuming data consolidation delays critical business decisions.

- Limited Analytical Capabilities: Fragmented data prevents comprehensive analysis and meaningful insights.

- Communication Breakdowns: Information silos impede effective communication between departments and trading partners.

Financial Challenges

- Higher Operating Costs: Inefficiencies across the supply chain increase costs in multiple areas:

- Higher inventory carrying costs

- Increased transportation expenses

- Additional labor requirements

- Emergency procurement at premium prices

2. Revenue Leakage:

- Lost sales due to stockouts

- Discounting to move excess inventory

- Customer attrition due to poor service

3. Capital Constraints:

- Excessive working capital tied up in inventory

- Suboptimal resource allocation

- Limited funds for strategic investments

Customer Impact

- Service Inconsistencies: Variable lead times and product availability create an unpredictable customer experience.

- Order Fulfillment Issues: Incomplete or incorrect orders damage customer trust and satisfaction.

- Reduced Competitiveness: Slower response to market changes and customer needs compared to more integrated competitors.

These challenges highlight the critical importance of integrating upstream and downstream supply chain systems into a cohesive whole, enabled by a truly comprehensive ERP solution.

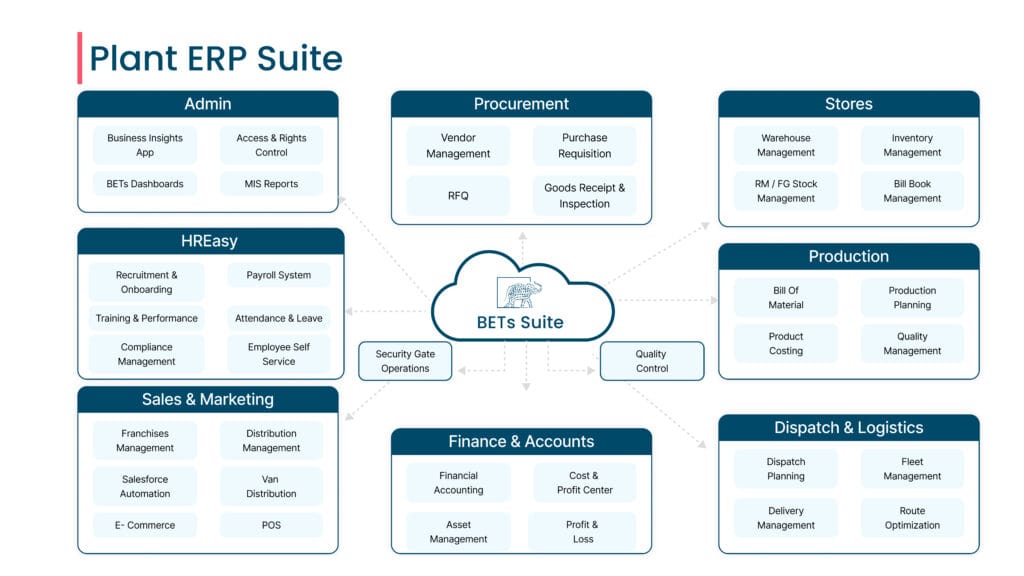

6. BETs 7 Platforms

Business Efficiency Technologies (BETs) offers a comprehensive suite of seven integrated platforms designed to create a seamless connection between upstream and downstream supply chain operations in SCM. These platforms work in harmony to eliminate silos, automate processes, and provide end-to-end visibility across the entire value chain.

6.1 BETs Platforms for Upstream SCM

- Vendor Relationship Management:

This platform goes beyond basic supplier databases to create true collaboration with vendors. It includes supplier onboarding, performance monitoring, quality management, and contract administration. The system enables strategic sourcing decisions based on total cost of ownership rather than just purchase price.

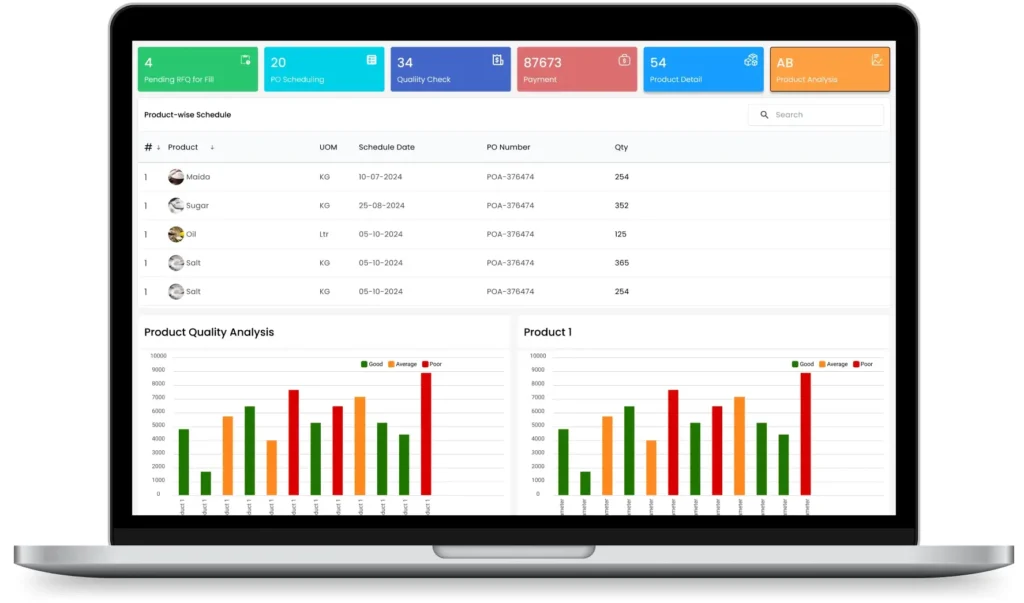

- Procurement Automation:

Streamlining the entire procure-to-pay process, this platform includes requisition management, purchase order processing, goods receipt, and invoice matching. By automating approval workflows and providing spend analytics, companies typically realize 5-15% savings on purchasing costs.

- Inventory and Stores Management:

This comprehensive solution manages all aspects of raw material handling, including receiving, quality inspection, storage location optimization, and issuance to production. Real-time inventory visibility prevents both stockouts and excess inventory.

- Production Planning and Execution:

At the heart of manufacturing operations, this platform handles production scheduling, resource allocation, machine maintenance, and shop floor control. It converts sales forecasts and orders into optimized production plans while managing constraints and dependencies.

The integration of these upstream platforms for SCM ensures that materials flow smoothly from suppliers to production, with minimal waste, optimal inventory levels, and maximum resource utilization.

6.2 BETs Platforms for Downstream SCM

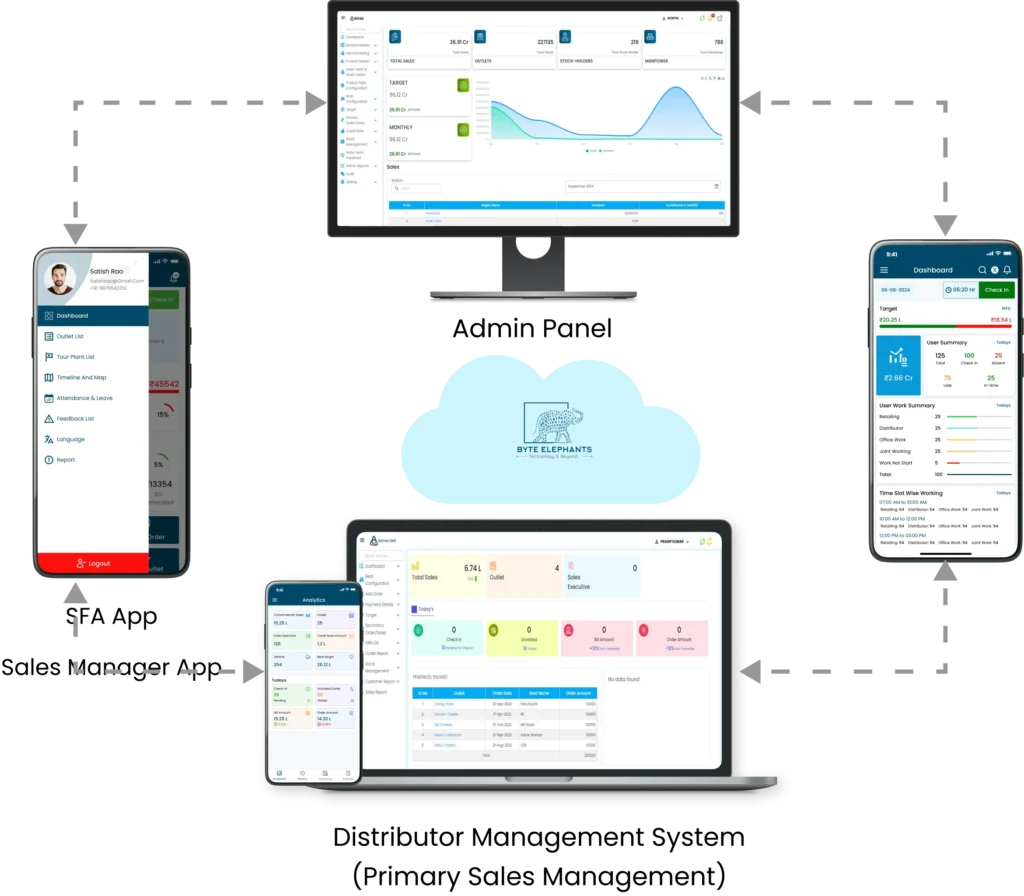

- Sales and Distribution Management:

This unified platform combines Sales Force Automation (SFA) and Distribution Management System (DMS) functionality. It supports the entire sales process from lead generation to order fulfillment, while managing distribution channels, pricing, promotions, and customer relationships.

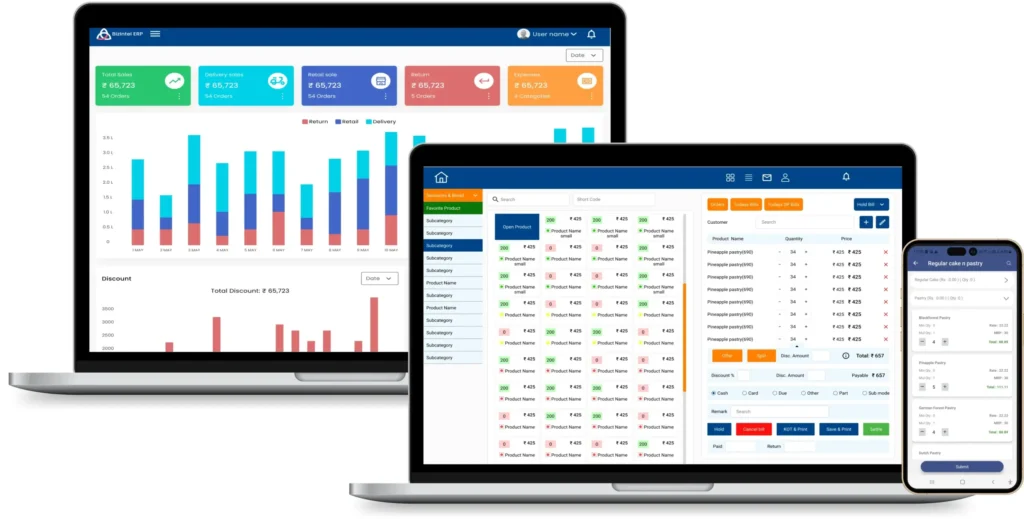

- Order Processing & POS:

Combining Point of Sale (POS) and Franchise Management System (FMS) capabilities, this platform ensures consistent customer experiences across owned and franchised locations. It handles transaction processing, inventory management at the retail level, franchise performance monitoring, and royalty calculation.

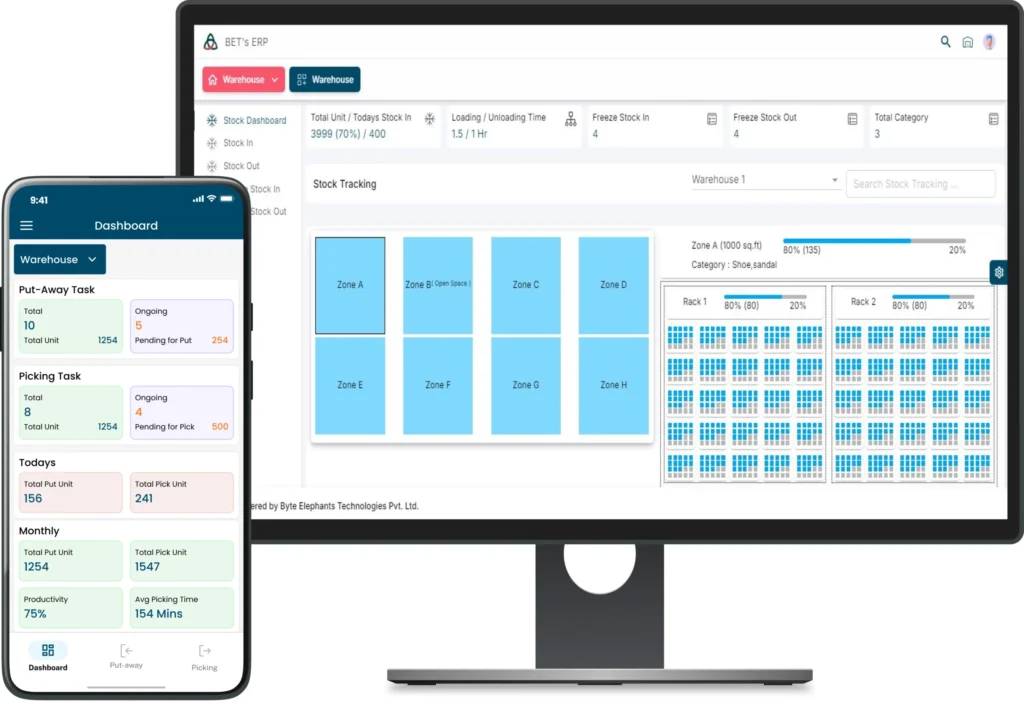

- Warehouse and Logistics Management:

This advanced solution optimizes finished goods storage, order picking, packing, and shipping operations. It includes route optimization, carrier selection, shipment tracking, and delivery confirmation to ensure products reach customers efficiently.

These downstream platforms for SCM ensure that finished products move smoothly to customers through various channels, with complete visibility and control throughout the process.

Integration of Both BETs SCM in ERP

What truly sets BETs apart is the seamless integration between these platforms. This integration occurs at multiple levels:

- Data Integration:

A single, consistent data model ensures information flows without translation errors or reconciliation needs. When a sales order is entered, it automatically impacts inventory projections, production requirements, and procurement plans.

- Process Integration:

Business processes flow naturally across traditional boundaries. Order fulfillment isn’t just a sales process or a warehouse process—it’s an end-to-end workflow that spans multiple departments with clear handoffs and responsibilities.

- Financial Integration:

All operational activities have financial implications that are captured in real-time. Revenue recognition, cost accounting, and profitability analysis are automated and accurate.

- Planning Integration:

Demand planning, production planning, procurement planning, and financial planning are synchronized to create a coherent business plan that all departments work toward.

- Analytics Integration:

Reports and dashboards draw from the entire operation, providing actionable insights that span functional boundaries. Executives can trace issues back to root causes, even when those causes cross departmental lines.

This comprehensive integration in SCM creates a digital nervous system for your business, where information flows freely and every part responds appropriately to changes anywhere in the system.

7. How is it a Game Changer for Brands? How Our Clients Benefitted Through This?

Implementing BETs integrated ERP platforms has transformed operations for numerous clients across industries. These success stories illustrate the tangible benefits of true end-to-end integration:

Case Study : Lutf Food - End-to-End SCM Integration Success

Company Profile:

- One central manufacturing plant

- Network of 120 retail shops across regions

- Product range including perishable food items with limited shelf life

- Rapid expansion strategy requiring scalable operations

BETs Implementation:

- Vendor Management System:

Streamlined relationships with all raw material suppliers, implemented digital quality checks, and automated reordering processes

- Procurement Management:

Established centralized procurement with automated vendor selection, competitive bidding, and contract management to optimize cost and quality of raw materials

- Multiple Stores Management:

Implemented synchronized inventory control across all 120 retail locations with automated replenishment thresholds and real-time stock visibility

- Production Management:

Connected financial, inventory, and production systems to create a unified operational backbone

- Dispatch & Logistics Management:

Enabled real-time fleet tracking, automated route planning, and delivery confirmation with electronic proof of delivery across all retail locations

- Warehouse Management System:

Optimized storage, picking, and packing processes for both raw materials and finished goods

- Distribution Management System:

Coordinated deliveries to all 120 shops with route optimization and real-time tracking

- Order Processing System:

Deployed automated order generation based on inventory levels, historical sales trends, and special promotions, with approval workflows and order status tracking

- Point of Sale Software:

Deployed across all retail locations with direct integration to central systems

Transformative Business Impacts

The integration of upstream and downstream supply chain operations in SCM through BETs 7 Platforms delivers game-changing benefits in several key areas:

1. Financial Performance

- Working Capital Optimization: Clients typically reduce inventory levels by 25-40% while improving product availability.

- Cost Reduction: Streamlined operations reduce labor costs, transportation expenses, and storage requirements.

- Revenue Enhancement: Improved product availability and customer service directly impact top-line growth.

- Margin Improvement: Better procurement practices and reduced waste contribute to higher gross margins.

2. Operational Excellence

- Process Efficiency: Automation and integration eliminate redundant tasks and streamline workflows.

- Resource Utilization: Better planning and visibility enable optimal use of production, storage, and transportation resources.

- Quality Improvement: Integrated quality management across the supply chain reduces defects and returns.

- Cycle Time Reduction: End-to-end process integration dramatically reduces order-to-delivery times.

3. Strategic Advantages

- Market Responsiveness: Real-time visibility enables rapid adaptation to changing market conditions.

- Innovation Enablement: Resources freed from firefighting can be redirected to value-adding activities.

- Scalability: Integrated systems provide a platform for sustainable growth without proportional cost increases.

- Sustainability: Optimized processes reduce waste, energy consumption, and carbon footprint.

4. Organizational Transformation

- Data-Driven Culture: Access to accurate, timely information fosters evidence-based decision-making.

- Cross-Functional Collaboration: Shared systems and information break down traditional silos.

- Talent Utilization: Automation of routine tasks allows employees to focus on strategic activities.

- Customer-Centricity: End-to-end visibility enables the organization to align all activities with customer needs.

These transformative impacts explain why organizations that implement BETs 7 Platforms typically achieve ROI in SCM within 12-18 months and continue to realize compound benefits as they fully leverage the capabilities of the integrated system.

8. Conclusion: Beyond Integration to Transformation

The journey from fragmented systems to a truly integrated ERP solution is not merely a technological upgrade—it represents a fundamental transformation in how businesses operate. By seamlessly connecting upstream and downstream supply chain in SCM processes through BETs 7 Platforms, organizations can achieve a level of operational excellence that was previously unattainable.

The Evolution of Supply Chain Management

Traditional approaches to supply chain management SCM treated upstream and downstream operations as separate domains, each with its own systems, processes, and priorities. This fragmentation created inevitable inefficiencies, conflicts, and missed opportunities. The BETs integrated approach recognizes that the supply chain is a single, continuous flow that must be managed holistically to achieve optimal results.

From Reactive to Proactive Management

Perhaps the most significant benefit of true supply chain integration in SCM is the shift from reactive to proactive management. Instead of constantly fighting fires caused by information gaps and process disconnects, leaders can anticipate challenges, identify opportunities, and make informed decisions that drive sustainable competitive advantage.

The Path Forward

For organizations still struggling with partial ERP implementations and fragmented supply chains, the path forward is clear:

- Assess the Current State: Conduct a thorough evaluation of existing systems, processes, and pain points.

- Envision the Future State: Define what true end-to-end integration would look like for your specific business.

- Develop a Roadmap: Create a phased implementation plan that delivers value at each stage.

- Select the Right Partner: Choose a solution provider with proven expertise in both upstream and downstream supply chain management SCM.

- Focus on People and Processes: Recognize that successful transformation requires attention to organizational change management, not just technology.

The Competitive Imperative

In today’s business environment, supply chain excellence in SCM is not optional—it’s a competitive imperative. Organizations that achieve true integration between upstream and downstream operations gain significant advantages in cost, efficiency, and customer service that translate directly to market leadership.

The BETs 7 Platforms offer a comprehensive, proven approach to achieving this integration, enabling organizations to transform their supply chains from a necessary cost center to a strategic asset that drives growth, profitability, and competitive advantage.

The question is no longer whether your organization needs integrated supply chain management SCM, but how quickly you can achieve it before competitors gain the advantages that true integration delivers.

Are you ready to transform your ERP from halfway there to fully integrated? The journey starts with a single step—recognizing the limitations of your current approach and embracing the possibilities that true end-to-end integration can deliver in SCM.